|

Turning/ Peeling

Long Bar & Tube Long Bar & Tube

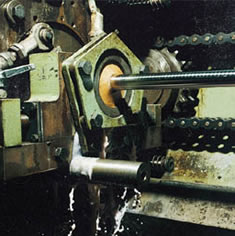

Surface enhancement through turning (also known as peeling) can provide benefits in many areas. High-speed centerless turning machines remove scale, cracks, seams, deformations, decarborized layers, and other imperfections resulting from hot or cold rolling, continuous casting, and other processes used for producing bar or tube.

BPC provides a wide range of capabilities utilizing high-speed, efficient turning centers providing dimensional control comparable to cold drawn material.

Target Products:

-

Helical Springs

- Bearing Applications

- Gear Applications

- Forging Applications

- CNC Machining Applications (reduced cycle time, increased productivity)

- API Pipe Steel

- Shaft Applications

- Boiler Tube

Attainable surface quality

Attainable surface quality

through turning of steel bar.

Turning/Peeling

by Location

|

Newton Falls,

Ohio

|

Chicago Hts.,

Illinois

|

Warren,

Michigan

|

Monroe,

Michigan

|

Wickliffe,

Ohio

|

|

Turning/

Peeling

|

0.625" to 4.750" diameter

10' to 36'

lengths

|

0.563" to

2.937" diameter

10'6" to 29'6"

lengths

|

0.5625" to 3.938"

diameter

10' to 45'

lengths

|

0.625" to 2.9375"

diameter

10' to 32'

lengths

|

0.750" to 10.400"

diameter

7'8"' to 40'

lengths

|

|

|

|