TURNING (PEELING)

CAPABILITIES

TURNING (PEELING)

LONG BAR & TUBE

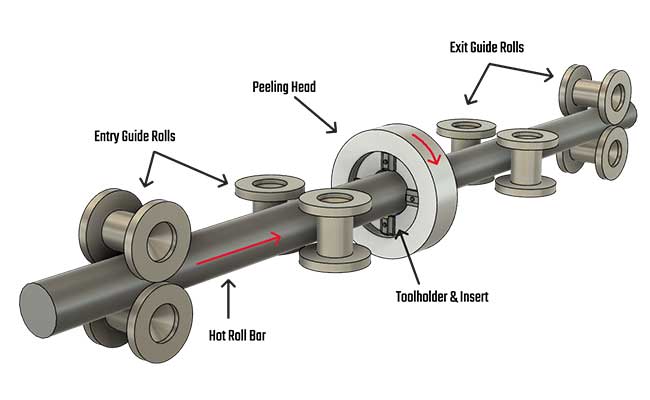

The steel bar turning (or peeling) process is a metalworking operation used to improve the surface finish, roundness, and dimensional accuracy of steel bars, typically made from carbon, alloy, or specialty steels. This process is often used to remove surface defects, scale, rust, and irregularities in the bar’s diameter, ensuring that the final product meets precise specifications.

BPC provides a wide range of capabilities utilizing high-speed, efficient turning centers providing dimensional control comparable to cold drawn material.

Advantages of Steel Bar Turning:

- Improved Surface Finish: The main advantage of peeling is the creation of a high quality surface, free of oxidation and scale.

- Increased Dimensional Accuracy: The process ensures that the steel bar meets tight tolerances for diameter and roundness.

- Increased Strength: By removing surface defects, peeling can reduce the risk of cracks and improve the overall structural integrity of the bar.

- Efficient Removal of Surface Defects: The peeling process is efficient for bars that have a rough surface due to forging or casting, helping to bring them to specifications.

- Increased Material Utilization: By removing only the necessary amount of material, the process minimizes waste.

- Improved Machinability: The smoother surface and improved dimensional accuracy make the bar easier to machine in subsequent processes.

Applications:

- Automotive Components

- Aerospace

- Precision Machining

- General Engineering

| Process | Warren, Michigan | Monroe, Michigan | Newton Falls, Ohio | Wickliffe, Ohio | Chicago Hts., Illinois |

|---|---|---|---|---|---|

| TURNING (PEELING) | |||||

| MAXIMUM INCOMING DIAMETER | 4.000″ | 3.000″ | 4.875″ | 10.800″ | 3.000″ |

| MIN/MAX FINISH DIAMETER | 0.5625″ – 3.9375″ | 0.625″ – 2.9375″ | 0.500″ – 4.750″ | .750″ – 10.400″ | 0.5625″ – 2.9375″ |

| MIN/MAX LENGTH | 10′- 45′ | 10′- 32′ | 10′- 36′ | 7’8″ – 40′ | 10’6″ – 29’6″ |

| Click Here to DOWNLOAD a Full Capability Summary by Location | |||||