STRAIGHTENING

CAPABILITIES

STRAIGHTENING

LONG BAR & TUBE STRAIGHTENING

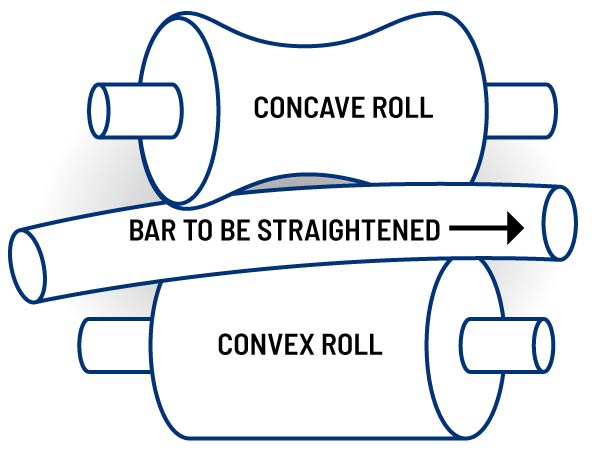

Straightening is typically the first operation in bar or tube finishing. Steel bar or tube is passed through a set of rolls (concave and convex) to improve straightness as well as remove rust and hot rolled scale. Straightening is performed to satisfy customer requirements and in preparation for additional processing.

Industry standard for a machine straightened bar is known as “Special Straightness”. Special Straightness requires that the bar not be out of straight by more than 1/8” in any 5 feet of bar length.

From 2 roll straightening of 1/2″ bar, to 5 roll straightening of 10 1/4″ bar or tube, BPC has the capability to perform the required service.

GAG PRESS STRAIGHTENING

Gag Press Straightening is used for shapes, billets, blooms, and round bars. The round or square bar is held at two points wherecounterforce is applied between the ends. Gag Press Straightening requires rotating workpieces and multiple “hits” to straighten product.

Gag Press Straightening is only available at our Wickliffe, OH facility.

| Process | Warren, Michigan | Monroe, Michigan | Newton Falls, Ohio | Wickliffe, Ohio | Chicago Hts., Illinois |

|---|---|---|---|---|---|

| BAR & TUBE ROLL STRAIGHTENING | |||||

| MIN/MAX DIAMETER | 0.5625″ – 4.000″ | 0.781″ – 3.125″ | 0.500″ – 4.875″ | 0.750″ – 10.800″ | 0.625″ – 4.000″ |

| MIN/MAX LENGTH* | 12′- 40′ | 10′- 38′ | 10′- 40′ | 10′- 45′ | 10′- 32′ |

| *DIAMETER DEPENDENT | |||||

| GAG PRESS STRAIGHTENING ROUNDS & SQUARES | |||||

| ROUNDS | – | – | – | 4.000″ – 10.000″ | – |

| SQUARES | – | – | – | 4.000″ – 10.000″ | – |

| LENGTH | – | – | – | 8′ – 45′ | – |

| Click Here to DOWNLOAD a Full Capability Summary by Location | |||||